Reduce Maintenance Costs,Improve Reliability, Increase Safety, & Lower Emissions

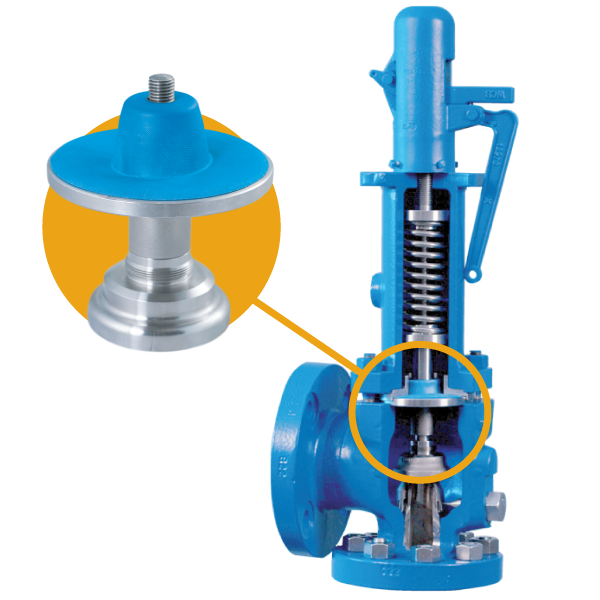

The Crosby J-Series with Balanced Diaphragm technology minimizes these risks by replacing the bellows with a flexible reinformed elastomer diaphragm. Diaphragms are inherently more resilient for higher backpressures and rapid pressure cycling applications. As a result, our new technology extends the backpressure limits to 80% of set pressure and increases the Kb factor up to 15%—expanding the application range of spring-loaded PRVs.